New Materials for Additive Manufacturing in the Refractory and Industrial Construction Sectors

Titanium aluminide is emerging as a significant material for manufacturing intricate structures through the Laser Powder Bed Fusion (LPBF) process, particularly in high-temperature applications.

The Fraunhofer IWU will showcase these advanced materials at the upcoming Formnext fair, taking place from November 18 to 21, 2025, in Frankfurt, Germany. Although the focus at the fair is on aerospace, the implications for the refractory and industrial construction sectors are profound.

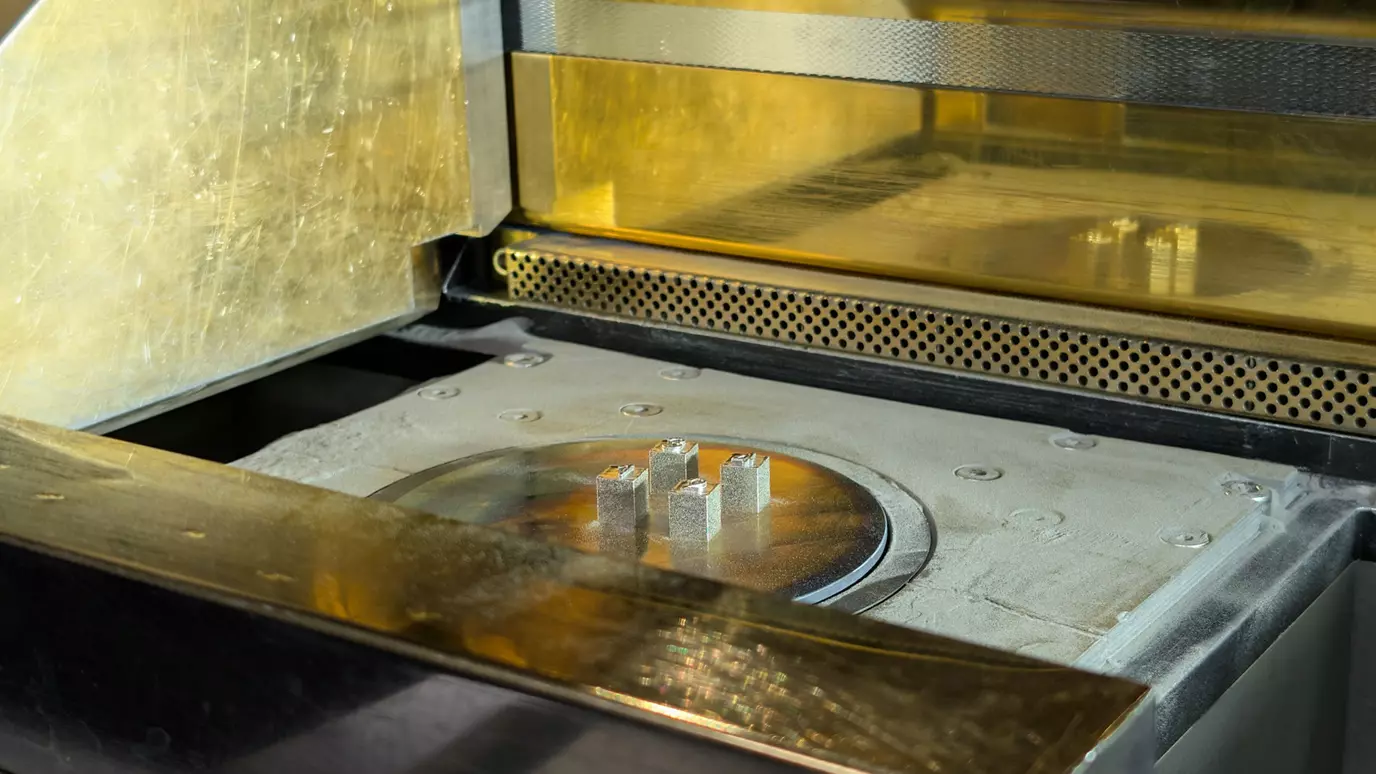

LPBF involves a laser that selectively melts layers of metal powder, creating components that boast exceptional geometric precision. Recently, Fraunhofer IWU has enhanced LPBF capabilities by acquiring a high-temperature system capable of preheating the powder bed to 1200 °C.

This breakthrough significantly improves the processing of refractory metals such as tungsten and titanium aluminide, which are crucial for producing durable structures. The advantages of high-temperature LPBF over traditional processing methods, like Electron Beam Melting (EBM), include:

- Higher resolution manufacturing, particularly for thin-walled structures, which is essential in applications such as heat exchangers and turbocharger systems.

- Superior control over the microstructure of components, leading to parts that are both lightweight and highly resistant to wear and extreme temperatures.

- Potential for creating high-performance engine parts that meet stringent operational demands in various industrial applications.

Furthermore, Aluminum Matrix Composites (AMCs) are gaining attention. These materials combine light weight with exceptional wear resistance, integrating particles like silicon carbide to enhance performance, particularly for automotive and aerospace use.

One notable innovation is Constellium’s Aheadd HT2, a heat-resistant aluminum alloy capable of withstanding service temperatures between 250–300°C. This capability facilitates the creation of more complex, lightweight structures with greater geometric flexibility when processed using LPBF technology.

In addition, the potential of additive manufacturing extends to die casting, where Fraunhofer ILT and MacLean-Fogg have successfully implemented scalable processes for producing large aluminum components.

In summary, the evolution of materials in additive manufacturing, especially those catered to high-temperature and refractory applications, presents numerous opportunities for contractors and plant engineers to optimize performance and efficiency in their projects.

Source: https://www.aluminium-journal.com/new-materials-for-additive-manufacturing