Optimizing processes and product quality in the refractory and industrial construction sectors has become increasingly vital. With the rise of digitalization, interactive visual data analysis tools have emerged as critical instruments for contractors and plant engineers, facilitating improved monitoring and understanding of production processes.

These advanced tools leverage massive volumes of production data from numerous sensors installed in industrial plants. By employing techniques such as machine learning and artificial intelligence, contractors can harness this data effectively to enhance production efficiency, reduce rejection rates, and ensure timely delivery of high-quality products.

Utilizing these visual data analysis tools offers several benefits:

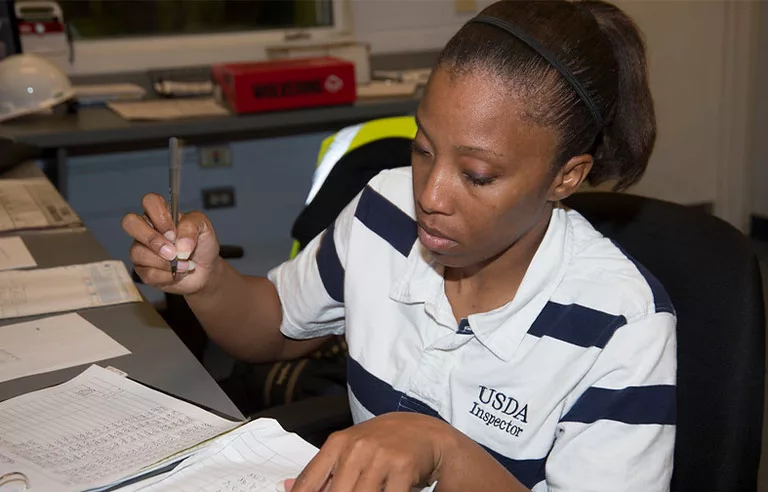

- Contractors and plant engineers can quickly identify correlations unseen in traditional analysis, thus addressing potential quality deviations early in the production cycle.

- Real-time monitoring enables the swift detection of anomalies, allowing for immediate corrective actions before quality is compromised.

- Improved communication between teams through clear visual data representation fosters better decision-making processes and collaborative problem-solving, minimizing downtime.

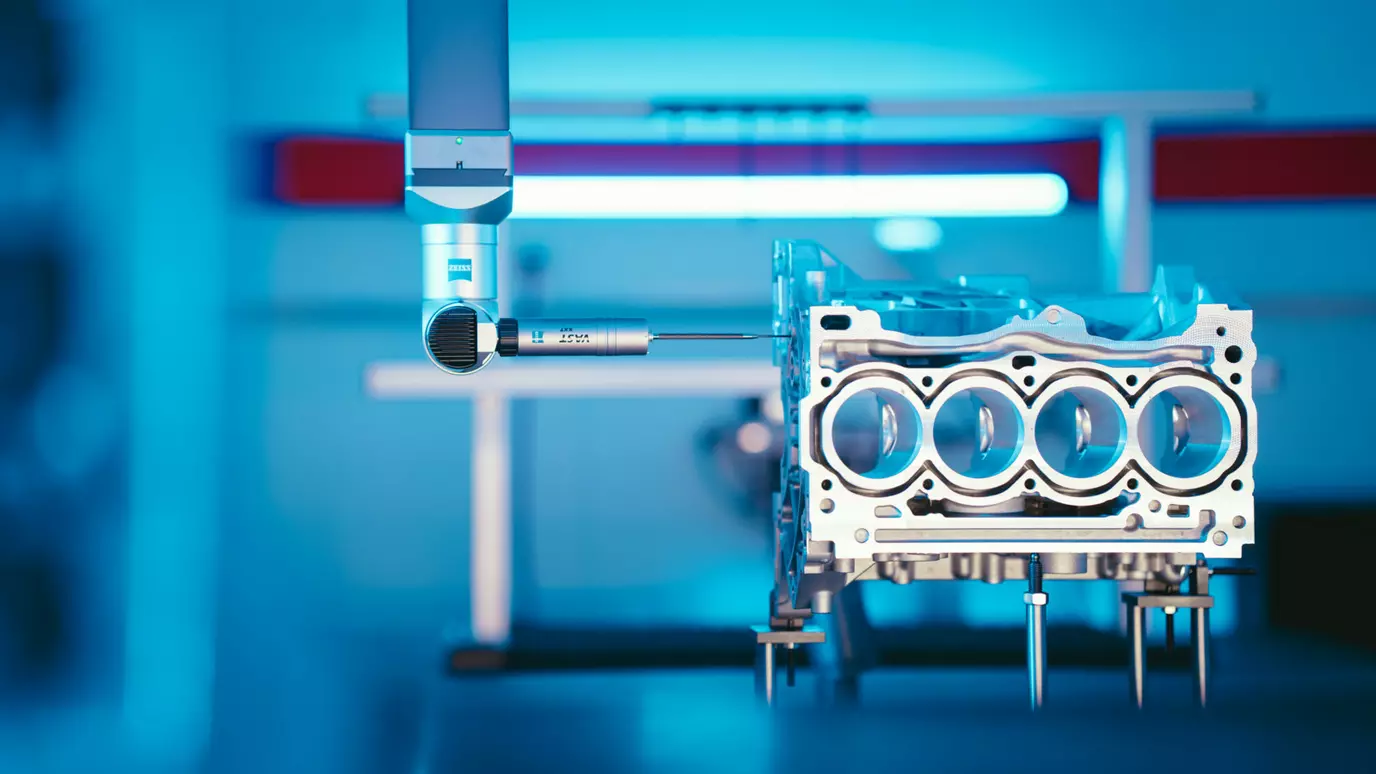

For instance, during the casting of refractory materials, identifying critical process parameters can significantly minimize defects, leading to better-quality products and optimized resource utilization. Tools like the ADAM (Aluminum Production Data Analysis and Monitoring) system are specifically designed to analyze production data, providing insights that drive process improvements.

As the industrial landscape continues to evolve with increased reliance on data, the importance of interactive visual analysis tools in achieving high standards of quality and operational efficiency cannot be understated. These tools are set to play a pivotal role in shaping the future of refractory and industrial construction.