Virtual Parts Run-In: Enhancing Productivity through Digital Twins

The manufacturing landscape is constantly evolving, and companies in the refractory and industrial construction sectors must adapt to remain competitive. One such advancement is the implementation of digital twins, a technology that Hanomag Aluminium Solutions has utilized to optimize its processes significantly. By leveraging a virtual model of their entire machine park, they were able to markedly reduce run-in time for new components.

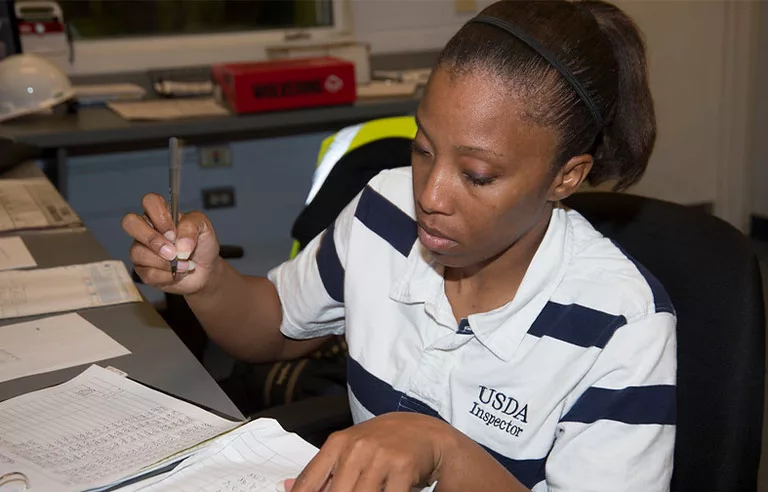

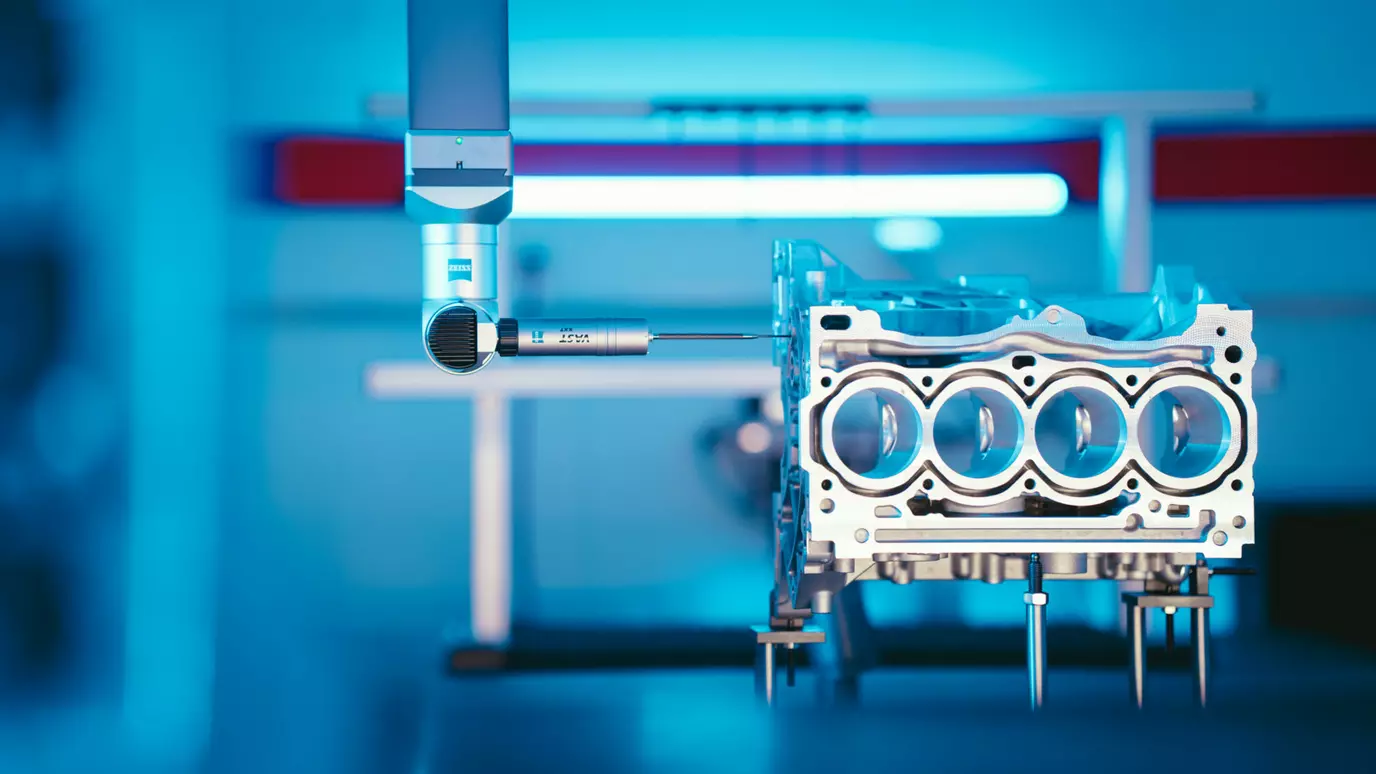

Hanomag Aluminium Solutions GmbH specializes in refining aluminum components, particularly for the automotive industry. By employing Siemens Xcelerator software, they created a comprehensive digital twin that allows for advanced simulations alongside actual production activities. This approach has enabled them to achieve a remarkable reduction in machine downtime during part run-in by as much as 90%, thereby optimizing productivity and enhancing the reliability of their quotation calculations.

- The use of digital twins allows contractors and plant engineers to simulate the production process before actual implementation, greatly reducing the risk of errors and unforeseen delays.

- Contractors can expect a significant reduction in retooling and run-in times, as virtual simulations enable a more streamlined workflow, lowering costs and enhancing turnaround times.

- The precise forecasting of processing times enhances pricing accuracy, making bids more competitive in a challenging market environment.

At Hanomag’s facilities in Kassel and Baunatal, they operate a diverse range of furnaces and CNC machining centers tailored to a variety of aluminum part specifications. Their production manager, Dominik Köhler, noted that the digital twin approach allows for programming and optimization to be conducted concurrently with manufacturing. This foresight significantly minimizes machine idle time caused by part run-in.

Digital twins not only permit extensive planning and scheduling improvements, but they also enable precise control over the machining process through real-time simulations using the Siemens Virtual NC Controller Kernel (VNCK). This advancement provides operators with the tools needed for effective machine control and optimizes tool path generation, ultimately leading to substantial gains in productivity.

In summary, the adoption of digital twins in industrial settings represents a pivotal shift toward more efficient manufacturing processes, enhancing both productivity and profitability for contractors and plant engineers alike.

Source: https://www.aluminium-journal.com/virtual-parts-run-in-digital-twin-increases-productivity