Enhancing Efficiency in the Refractory and Industrial Construction Industries with Assembly Line Equipment

In today’s competitive landscape, the importance of efficient manufacturing processes cannot be overstated. Whether it’s producing refractories for high-temperature applications or constructing complex industrial structures, understanding the role of assembly line equipment is crucial for contractors and plant engineers.

What Is Assembly Line Equipment?

Assembly line equipment refers to the machinery and tools that facilitate organized production. It consists of workstations where machines and operators undertake repetitive tasks, ensuring a streamlined approach from raw materials to finished products. The types of equipment used may include:

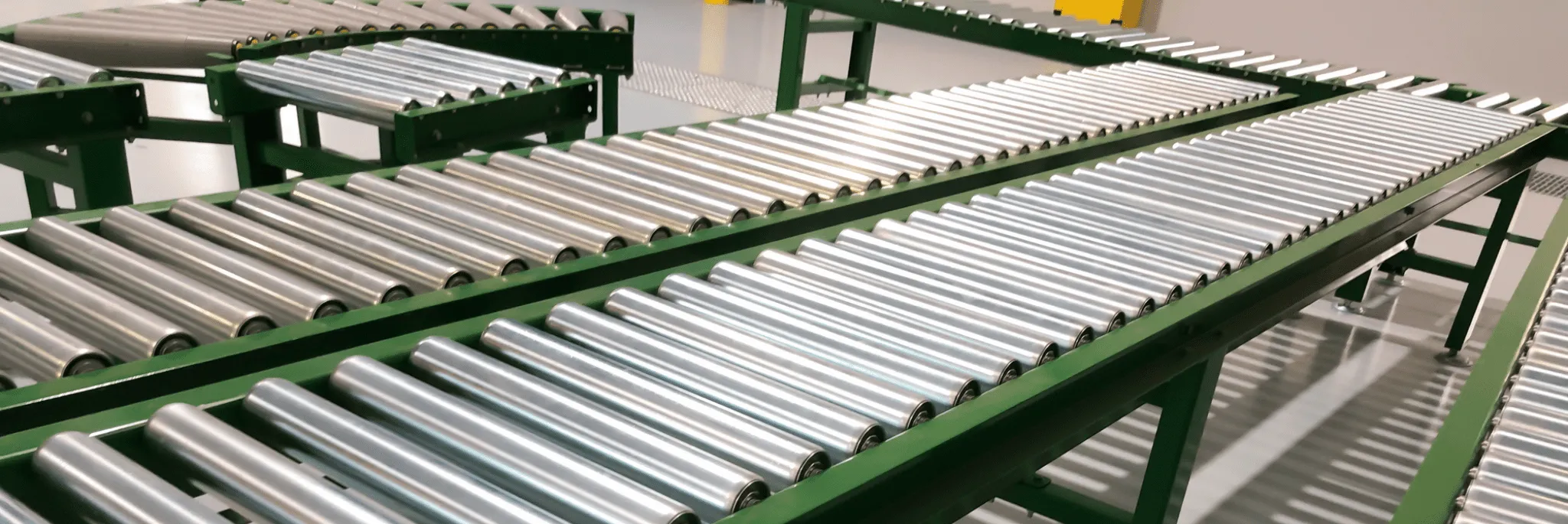

- Conveyor Systems: For seamless material transport between different production points, minimizing manual handling and downtime.

- Automated Assembly Machines: Such as welding and fastening tools, essential for high precision in manufacturing refractories and components.

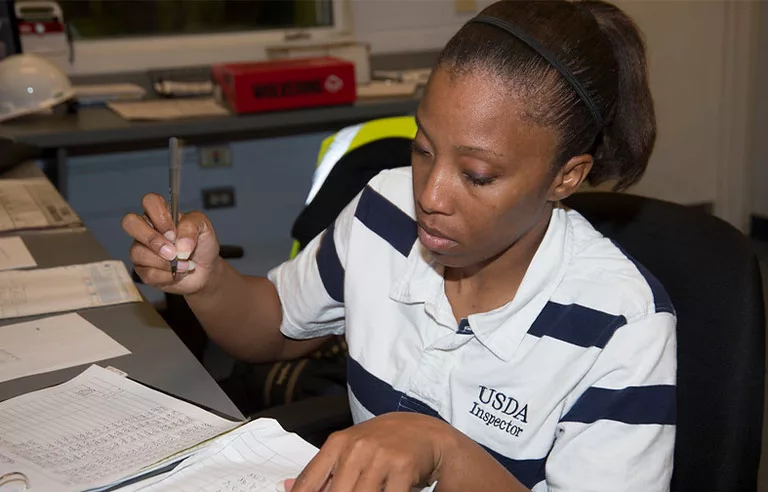

- Inspection Tools: For quality assurance, these ensure that every product meets stringent industry standards.

The Impact of Assembly Lines on Industrial Construction

Assembly lines play a pivotal role in modern industrial manufacturing by creating structured processes that enhance efficiency and reliability. Key benefits include:

- Continuous Flow: Automated systems reduce idle time and maintain a steady movement of materials, which is vital in settings like refractory production where timing is critical.

- Improved Quality Control: Advanced inspection technologies help detect flaws at early stages, ensuring high-quality standards in construction projects.

- Worker Ergonomics: Automated tools alleviate excessive manual labor, allowing skilled workers to focus on complex tasks that require human judgment.

Adapting Assembly Lines for the Refractory Sector

As the refractory industry embraces automation, flexibility and adaptability are essential. Assembly lines can be modified to handle various products as designs change or demand fluctuates. For instance, programmable machinery allows for quick reconfiguration, ensuring that production aligns with market needs without compromising safety or productivity.

Cost Efficiency and Resource Utilization

While the initial investment in assembly line technology can seem significant, the long-term benefits are substantial. Lower labor costs, reduced scrap, and enhanced production reliability yield a favorable return on investment. Automated systems can operate beyond normal human limits, facilitating more extensive production runs and minimizing operational costs.

Conclusion

As industries evolve, adopting assembly line equipment becomes essential for contractors and engineers in the refractory and industrial construction sectors. Understanding and implementing these systems can lead to improved output, enhanced safety, and ultimately greater profitability.

Source: https://ezgmfg.com/how-assembly-line-equipment-improves-output/